Thanks to everyone who ordered an Allagash Cruiser or Dirigo Belt Axe and has been so patient waiting for us to get them into your hands. We appreciate your trust and understanding. Over the last few months we have been making changes to increase axe production but doing so without sacrificing quality and still maintaining a COVID safe workspace for our blacksmiths. These upgrades include new machines, increased hours at the shop and new makers.

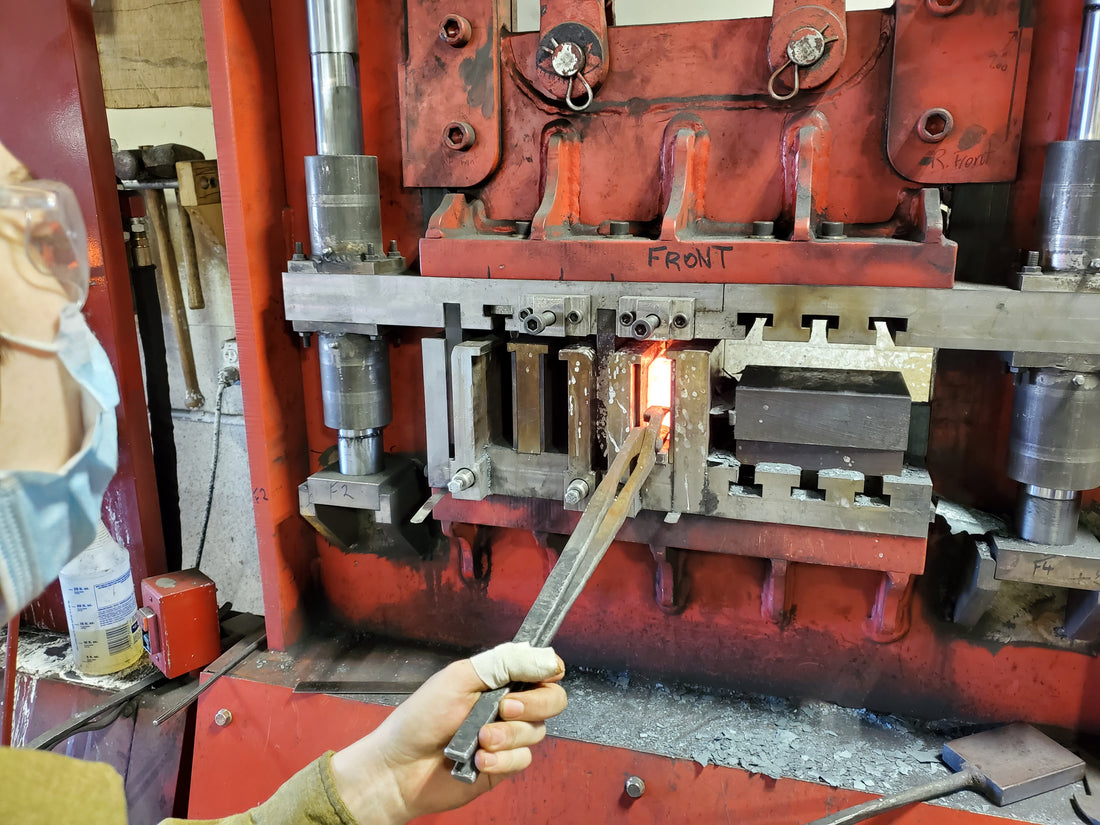

Our 50-ton press is now fully operational. While we did use it in 2020, we did not have the final die set completed. This new set-up allows us to square, punch and fuller without swapping out dies like we had to do with our 25 ton press. This reduces the number of heats needed (and propane used) per axe and increases the number of axes we can forge in a week.

We recently bought a treadle hammer to make stamping our logo, year of manufacture and blacksmith’s initial on our axes faster, more consistent and safer. If you watched one person hold the stamp while the other swings a hammer down on a red-hot piece of steel you would want one of these treadle hammers too! The treadle hammer’s carbon footprint is zero as it is powered with good old foot power. Nice!

One of our big bottle necks has been grinding. After we forge the axe we grind the axes using our 2” x 72” Bader belt grinders. These machines have been workhorses for us, but the time has come for an upgrade. Our new 6” x 79” belt grinder spins at operates at 7400 rpm. Coupled with a 36 grit belt we can now remove stock at ludicrous speed (as Dark Helmet might say) leaving less finish grinding and speeding production.

Finally, we purchased a new belt sander to use in the wood shop to help Tanner when he is hafting axes. Now he no longer needs to kick someone off the Bader in the metal shop.

Increased Shop Hours

To keep up with demand we are now working in the shop seven days a week. From Tuesday to Friday we are working two shifts. This has increased production and allowed us to train our new smiths more quickly.

Meet Our New Makers!

While these folks have been with us since late last year, they are probably new to you so please welcome Aidia Sandlin, Justin Glover and Adam Fowler. All of these talented assistant blacksmiths come to us from the Maine College of Art.

Take a Peek Behind The Scenes at B&C

One of our goals in 2021 is to shoot more video of our axe making process and allow you a peak behind the scenes here at Brant & Cochran. Our first video of 2021 shows our Tanner Wilcox demonstrating the art behind hafting our axes.

Thanks again for your support, patience and understanding as we grow.